The Associated Chambers of Commerce and Industry of India (ASSOCHAM) in an analysis last year had stated that the Indian packaged food industry is expected to reach the $30 billion mark by 2015 growing at a CAGR of 15%-20% p.a. The current level of the food industry is currently US$ 15 billion including snacks, ready –to-eat food, processed food etc.

In the early part of 2013 in a summit held for flexible packaging industry (Indiapack 2013) it was ascertained that the Indian packaging industry is expected to grow at 12.3% CAGR in the next 4-5 years to become the fourth largest global market with a sale of $ 42.7 billion

The growth of these two markets is mutual. The rapid urbanization, modern retail trade, technological advancements are some features which have prompted a boost in these sectors.

In the flexible packaging market food packaging is estimated to be the second fastest growing market due to a rise in consumption of packaged food items. A growing sense of concern of health and knowledge about the nutrition of the food packaged has driven the market for packaged food to preserve the end products.

In the past few years the Indian food industry has grown from strength to strength. India comes second to China as food producer with a potential of being number one in the world. Packaged food has become the new preferred source of consumption especially in the urban areas. Packaged food saves both time and energy consumed in cooking a full blown meal from scratch.

Flexible Packaging has benefitted immensely from the explosion of various brands. Materials like BOPET, EVOH and PA have been demonstrating high growth owing to their barrier properties. Barrier flexible packaging has seen a continuous growth as major manufacturers demand packaging that will ensure longer shelf life and greater protection for their produce.

Other features like durability, convenience, designabilitiy, eco-friendliness etc have been desirable in making flexible packaging a favourite amongst food manufacturers.

Flexible Packaging has the advantage of using pouches of the same style to store different items. A basic pouch can be used for storage of food and beverage. By adding a spout to the pouch it can be customized to store liquids. The addition of a zipper will make the pouch more convenient to store and restore dry items.

The main categories of food that involve flexible packaging are bakery items, dried and frozen processed food, food substitutes, dairy products, processed meat etc. According to the Indian Brand Equity Foundation (IBEF) the packaged food industry in India is likely to witness a jump by 2015 and touch US$ 30 billion from the current US$ 15 billion. This rise will be mainly due to the rise in household income, changing urban lifestyle and retail trade. In 2011, residents of urban areas were the largest consumers of processed food, consuming 78% of total packaged food.

Beverages also form an important share in the flexible packaging sector. The fruit beverage category accounts for US$ 177.78 million and is expected to grow at a CAGR of 15% over the next three years.The packaged milk segment in India is projected to grow from the present US$ 7.76 billion to US$ 32.9 billion by the year 2030 at the rate of 8%.

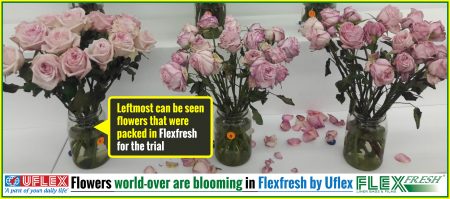

India’s largest flexible packaging company UFlex Ltd believes that flexible packaging is one of the main ingredients of the food and beverage industry owing to its dynamic structure and nature. Many innovations which have become a part of the FMCG industry are products of the flexible packaging industry. Apart from that, top of the line designs and recyclable plastics have been our bastion for last many years. UFlex products are designed keeping in mind the changing market trends and consumer needs and specifications.