In the Global Hunger Index 2014, India ranked at 55th position among 76 emerging economies. It trails behind countries like Thailand, China, Ghana, Sri Lanka, Iraq and Nepal. What is even more worrying is that a third of world’s undernourished children are in India. Despite that, a UNDP report states that upto 40% of the food produced in India is wasted. According to the agriculture ministry, food worth Rs. 50,000 crore is wasted every year in the country.

Wastage of food is not only suggestive of hunger but also of economic problems such as inflation. In this blog we will discuss how flexible packaging can help in reduction of food wastage. First let us list out some of the reasons leading to food wastage in the food supply chain:

- Agricultural stage: damage from pests and disease; unpredictable weather conditions; not meeting quality specifications.

- Post-harvest handling and storage: not meeting specifications for quality and/or appearance pest damage spillage and degradation lack of proper storage facilities.

- Processing and packaging: trimmings and other food preparation waste; production line start up batch mistakes inadequate remaining shelf life.

- Distribution: damage in transit/storage due to packaging failures; product spoilage; fresh produce not meeting specifications or damaged during handling inadequate remaining shelf life due to poor stock rotation or low sales.

- Food service: trimmings and other food preparation waste; poor inventory management (e.g. over-ordering) improper food handling confusion over expiry date; plate leftovers.

- End consumer: trimmings and other food preparation waste food spoilage preparing too much food; past expiry date; plate leftovers.

The flexible packaging industry has the ability to be a part of the solution since it is adept at offering packaging in different sizes innovations that help extend the shelf life of the product and keep it safe and also sustainability of the package.

Over the last few years, innovations in terms of product development like absorbing food odours, retard oxygen migration, and preserve food longer, has been driving flexible packaging. Flexible packaging engineers have incorporated new materials into the films which lead to a longer shelf life and improved quality. Other than that this form of packaging acts as a barrier against moisture, microbes, change in temperatures, dirt etc thereby greatly extending the shelf life of food and check spoilage, leading to less food waste.

To ensure safety of the packaged product an ideal flexible package should consist of the following features:

- Increased barrier protection

- Preventing substances which can lead to spoilage

- Detection of spoilage

- Recyclable

- Cost effective

- Suitable for contact with food

- Have high standard of health, safety and sustainability

Flexible packaging helps reduce wastage of food from 3% to 1% by increasing the shelf life according to the Industry Council for Research and Packaging on the Environment (INCPEN). Products like vegetables, dairy have a longer shelf life thanks to smart packaging. Innovative packaging designs for milk pouches are making the transportation of milk without refrigeration possible.

Temperature variations in packed food can result in compromising its safety and quality. Driven by rapid advancements in time-temperature indicators (TTI), intelligent packaging is anticipated to witness a strong growth. This system could be able to detect food contamination and change of color in case the food is not fit for consumption by the consumer.Another innovation which can assist in cutting short the wastage of food is Aseptic packaging. This technology helps sterilize the package and the food product separately and then combine and seal it under a sterilize environment. This trend is fast picking up and is expected to lead in the coming years. Currently the Aseptic packaging market is at $35.8 billion and is expected to continue the upward spiral due to the consumers demanding chemical- free, natural and fresh food and beverages.

By extending the lifecycle of food and protecting it against foreign elements, smart packaging can ensure that the consumed products are safe and nutritious and hence help in improving the sustainability of the food item.

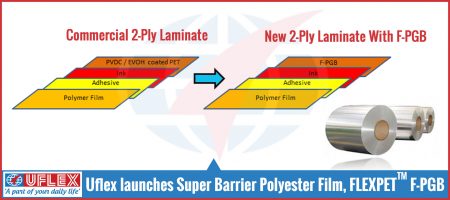

UFlex Ltd. believes that flexible packaging is an investment in protection of food and the resources that are used to produce it. UFlex manufactures plastic materials like BOPET, BOPP and Laminates which have high growth owing to their barrier properties. Barrier flexible packaging has seen a continuous growth as major manufacturers demand packaging that will ensure longer shelf life and greater protection for their produce.