February 13, 2020, Noida: UFlex Ltd., India’s largest multinational Flexible Packaging Company and a global player in polymer sciences, today declared its earnings for the quarter ended December 31, 2019. Consolidated EBITDA for Q3 FY19-20 stood at INR 276.4cr, showing a jump of 21.4% on a YoY basis while its consolidated net profit was up 56.7% YoY at INR 84.6 cr.

The Total Production Volume during the quarter was 93161 metric tonnes (MT) as compared to 96876 MT during the December 2018 quarter, while Total Sales Volume for the quarter was 91842 MT vis-à-vis 94229 MT in the December 2018 quarter. The company reported consolidated net revenues of INR 1801cr for the third quarter of fiscal 2019-20, as compared to INR 1981cr in same period last year.

Talking about the earnings for the company, Rajesh Bhatia, Global CFO, UFlex Ltd. said, “Q3 FY2019-20 was extremely exciting for us, from being ranked at 188 among India’s Fortune 500 to India Ratings upgrading us to IND ‘A’ ratings”. Adding, “Overall, operating EBITDA margins of 15% was achieved for the quarter driven by higher margins in Packaging Films Business and higher volumes in Packaging Business. In FY21, the company’s Greenfield plants in Russia, Nigeria, and Hungary will become operational and will add to the topline and profitability. The production, sales volume, and net revenue in Q3 were lower marginally due to the closure of one BOPET line in Dubai which is being shifted to Russia, but the Operating EBITDA was still up 19% YoY. It is heartening to see that the Packaging Business production volume in Q3 is up by 11% approx.”

Reinforcing the efforts by the company towards sustainability, Ashok Chaturvedi, CMD, UFlex Limited said, “The industry-led by UFlex has got together to form Multi-Layer Plastics Films Sanitation Trust (MLPFST) that is partnering with State Governments to set up municipal solid waste sorting and segregation plant that will separate the plastic recoverable from mixed garbage via automated technology and recycle MLP waste into granules for making various plastic items including buckets, mugs, flower pots, outdoor furniture and many more. MLPFST has started off this project with the set-up of a pilot plant in Bengaluru and another one to be established at a leading tourist destination in North India later. This step validates our efforts to lead our industry in changing the myth around plastic and ensure that plastic reaches the right stream for its recovery.”

Some key product launches in this quarter by UFlex that will change the way the market functions

- New Products by Chemicals to Promote Sustainability: With an objective to promote sustainability, UFlex Chemicals Business launched three new products for the global markets that included :-

- FLEXSEAL Blister Coating– A water-based PUD used as heat sealable paperboard overprint varnish for sealing PET or PVC blisters and fold-over packages.

- Aqueous Narrow Web Inks– Inks that were specially created to replace solvent-based wide web flexo inks for high-end food packaging applications.

- Aqueous water resistant OPV- Superior scuff and water resistant properties for deep-freeze and food wrap application.

- Engineering Innovations for Pharma Packaging: In order to value add to the pharma industry, the Engineering business of UFlex developed machines that further push the pharma Packaging Industry towards a brighter future.

- Rotogravure Printing Press Designed to Print on Aluminum Foil- ‘Rotoflex Stanmas 20’ is an engineering innovation by UFlex that strengthens the portfolio of Rotogravure printing machine it already offers. This machine can be used for printing multiple substrates and can print on aluminium foil of varying thickness as well as other substrates spread over polymer family and paper. The ideal printing speed on the machine is 150 meters/minute for aluminium foil, while other substrates can run upto 200 meters/minute. The press that prints with solvent-based inks, also comes affixed with the unique feature of an Electrical Heating. Suitable for narrow web application, Rotoflex Stanmas 20 is a mechanical line shaft that can stretch upto 8 colours configuration. UFlex has developed the machine with technical inputs from MRG Grafomac of Italy and in-house design team. Kalyar Replica, a leading flexible packaging convertor in Bangladesh, has been the first buyer of a special purpose 4-colour Rotoflex Stanmas 20 for pharma packaging.

- Multi-Lane Stick Pack Machine VFFS for Packing of Single-dose Pharma Products- Multitrack Stick Pack Machine by UFlex( Model Stick Pack 200) is a five-lane machine for packing powder, granules and paste at a speed of up to 250 sticks per minute. This machine can pack content in center seal tubular-shaped sachets ranging in weight from 1gm to 20 gm and is best used for pharma products that can be consumed in a single dose.

- A Stylish Revival to Aseptic Packaging with Lens Effect: UFlex launched a cutting-edge packaging solution with lens effect called ‘Asepto Eye’ for the beverages segment. Asepto Eye is a ripple concave lens and single lens technology that gives 3-D effects on the aseptic packs. These lenses come in various sizes & shapes and offers bespoke artwork, as per the brand owner’s requirements. The newest offering from Asepto gives myriad choices to beverage manufacturers to be distinct on the shelves, and also add a premium value to their brand through UFlex packaging.

- Aesthetic Enhancement & Anti Counterfeit Solutions for Labels & Stationary Industry: With its range of advanced Holographic Solutions developed, UFlex is ready to give a facelift to Books, Labels & Stationary, Cartons and Textile industry:-

- Developed Registered De-metalized Holographic Tape which is hot stamped on product labels and is made with 19 micron PET base film. This solution that is used as an anti-counterfeit feature targets India as well as Export markets.

- Soft Touch Lamination film for Carton Packaging is available in PET as well as BOPP base films. In this, the film is induced with a special coating that gives a smooth and silky touch effect adding to the aesthetics of the product that it is applied to. A product that largely targets Indian customers has found takers in segments like Stationary, Product Catalogues, Books, Cartons Labels etc.

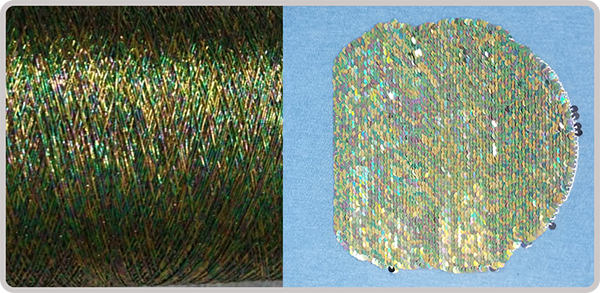

- Dhoop Chaon Design for Hot Stamping Foil is a unique offering by Holographic Business of UFlex which enables hot stamping coatings on 12 micron PET base film to give special effects, without holography. This product has got customers’ attention in Surat Textile market especially for fabrics required to create fashion clothing, home furnishing & other decorative products. Dhoop Chaon design is also applicable in Graphic Grade in Cartons, Labels & Stationary, Books and more.

- Multi-colour Rainbow Stamping Foil that augments aesthetic and shelf appeal of a product has been developed for stationary products. Achieved by hot stamping on a 12 micron PET base film with multi-colour printed foils, the solution also serves as an anti-counterfeit tool and is advantageous for Cartons, Labels, Stationary industry.

- Laser Embossed Cylinder for Hand Embossing Effect: Getting hand embossing effect on a table cover, curtain and wall paper have been made possible with the launch of Laser Embossed Cylinders by UFlex. Targeting niche markets with this product, the Cylinder Business of UFlex is already witnessing an upsurge in demand in the domestic as well as international markets.