‘Necessity is the mother of invention’, goes the age old adage. At India’s largest global flexible packaging solution company UFlex Limited, every necessity is viewed as an opportunity and the most optimum solution is engineered to fulfill it.

How to design a zero speed splicing system for continuous operation on woven polypropylene (WPP) as the base web was a daunting challenge that confronted the converters servicing the packaging requirements of building materials brands.

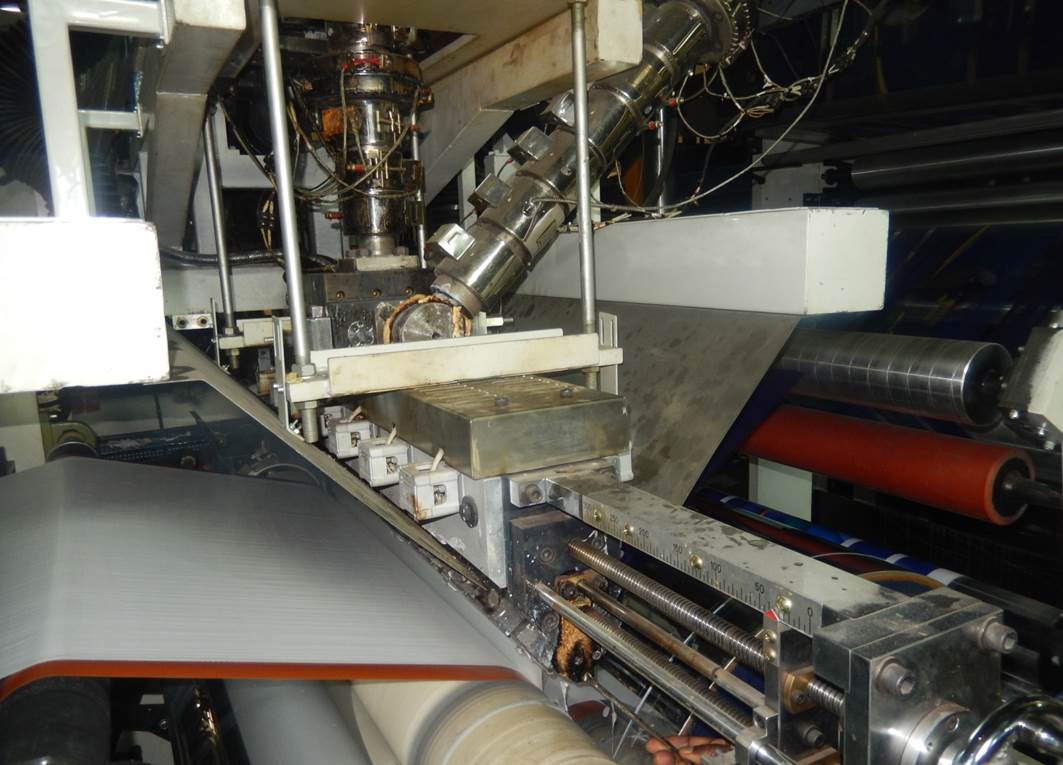

Converters and packaging companies have all too often faced difficulties while laminating a woven web owing to the troughs and valleys (also called warps and wefts) that are inherent part of the texture. In response to this, the engineers at UFlex designed the EL-1300 Extrusion Lamination Machine that seamlessly carries out the process of lamination for woven propylene simultaneously offering the following benefits:

(a) Attainable lamination speed of 250 m/minute;

(b) Corona treaters to seamlessly integrate treater into flexible packaging extrusion coating & lamination lines;

(c) Independent drives for all segments of the machine;

(d) Heavy Duty (Sturdy) structure;

(e) Motorized three axis movement of carriage for air gap setting;

(f) Chamber type doctor blade for anchor coating;

(g) T-Die with internal duckling & lip opening up to 1mm;

(h) Unique design of lamination drum to maintain even temperature across the width;

(i) Sleeve type coating nip as optional;

(j) Turret type unwind & rewind;

(k) AC vector grade motor with digital AC vector drives.

This extrusion lamination machine is equally efficient to laminate very thin LDPE substrates to woven polypropylene and also to paper/any packaging film.

Except for some electrical and electronic parts, most of the mechanical parts have been fabricated and assembled in-house at UFlex Engineering plant in Noida. The Extrusion Lamination Machine owing to its very many advantages is much in demand across the country particularly when no other company offers it in India.

Mr. Ashok Chaturvedi, Chairman & Managing Director, UFlex Limited said, “Our USP lies in the very fact that we are a fully integrated flexible packaging solution company. If on one hand we can offer laminates as rolls and pre-formed pouch, with equal ease on the hand we can offer machines that can form packs out of those rolls, fill the product in them and seal it to your satisfaction too. We also offer a wide array of printing and lamination machines that are capable of carrying out high precision converting processes to make these laminates.”

“From PET chips i.e. raw material for manufacturing polyester films to speciality packaging films, to laminated flexi-tubes and big bags we make them all. From rotogravure printing cylinders, flexo-polymer plates, elastomers and sleeves to inks, adhesives, coatings and polyols used in the converting process we make them all. If the threat of counterfeiting is what worries you, we offer the most contemporary and technologically superior brand protection and anti-counterfeiting solutions that will keep the fake and spurious at bay.

Thus at UFlex, ours is a 360° approach towards addressing varied flexible packaging needs of our clients across the globe,”said Mr. Chaturvedi.

Visit UFlex at HALL NO 11, STALL 11.21 at Pack Plus 2016, Pragati Maidan New Delhi from 27-30 July 2016