India’s largest multinational flexible packaging materials and solution company UFlex has launched Super Barrier Polyester Film, FLEXPETTM F-PGB-12.

This 12 micron Bi-axially Oriented Polyethylene Terephthalate (BOPET) film owing to a specially modified surface treatment (on one side)offers very high barrier to oxygen. The other side of the film can be corona treated or left untreated as per the requirements of the convertor. The Oxygen Transmission Rate (O.T.R) of this film is < 6 cm3/m2/day at 23 degrees Celsius & 0% RH. A big advantage with this film is the fact that it does not require any coating or co-extrusion of Polyvinylidene Chloride (PVDC) or Ethylene Vinyl alcohol (EVOH) for enhancing barrier properties.

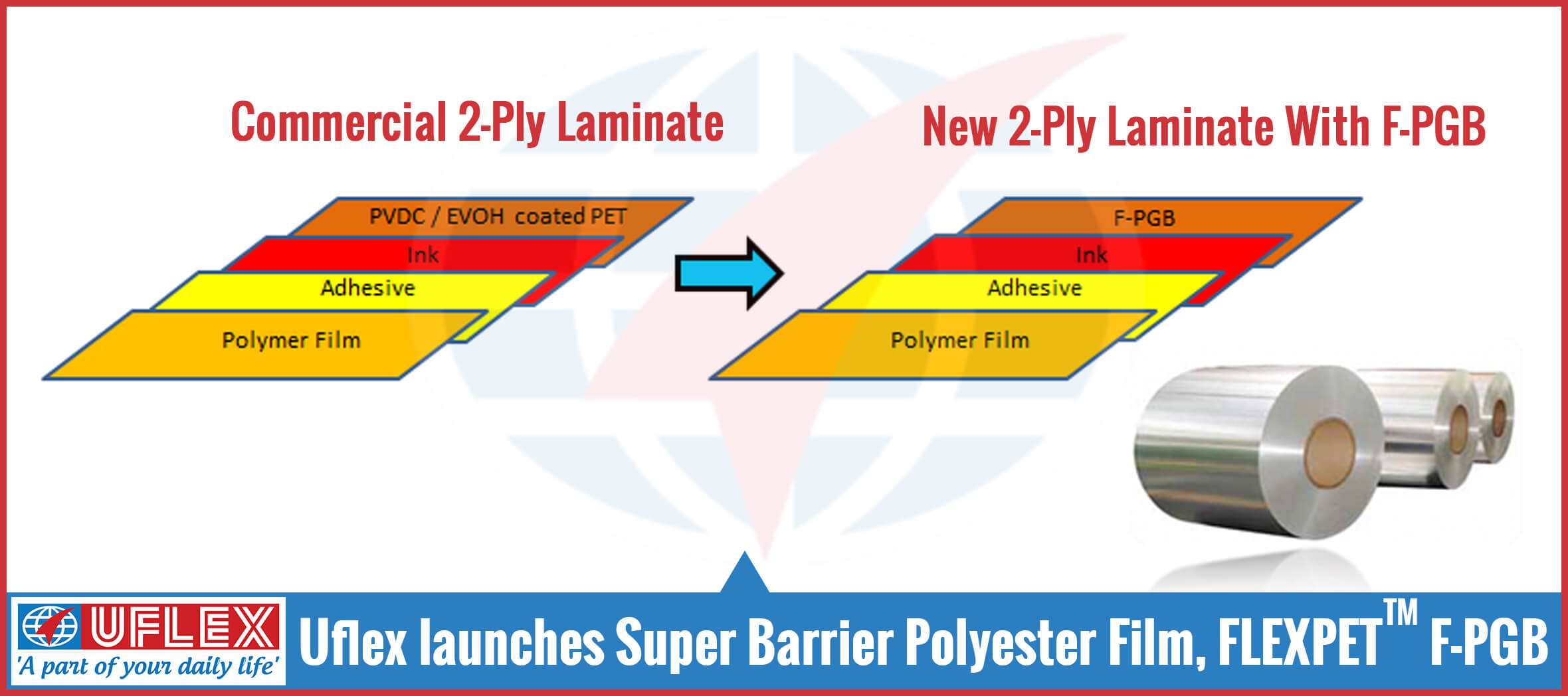

An untreated BOPET normal film of 12 micron has O.T.R. as high as 135 cm3/m2/day; thereby offering much weaker barrier to O2. A normal film quite essentially requires inline or offline PVDC/EVOH coating for enhancing the barrier properties.

The benefits of FLEXPETTMF-PGB-12 filmare multifarious:

- It offers good flexibility;

- Exhibits very good optical properties/ transparency;

- Offers good machinability and handling properties owing to high Tensile Strength at Break (TSB);

- Poses excellent barrier to gas as compared to normal BOPET Film.

- Offers cost benefits w.r.t. PVDC/EVOH coated/co-extruded substrates.

Mr. J.K. Sharma, AGM, Technical Service and New Product Development (Films) talking about the USPs of FLEXPETTMF-PGB-12 said, “This film offers a clear cost advantage to the convertors over other PVDC/EVOH coated/ co-extruded films and is widely used in the packaging for pet foods roasted coffee and other oxygen & barrier sensitive food products. There is a huge demand for this cost effective speciality BOPET film and we are getting good number of business enquiries.”

Giving more details about the new speciality film, Mr. Pramod Sirsamkar, President Technical & New Product Development (Films), UFlex Limited said, “In a typical two ply laminate our latest film can serve as a superior oxygen barrier while the sealant layer can act as a great barrier to moisture. This is the simplest cross section that one can think of keeping the converting costs to a bare minimum without compromising upon the performance of the laminate. The F-PGB film complies with EU regulation and US FDA for food contact application.”

Commenting about FLEXPETTMF-PGB-12 film, Mr. Ashok Chaturvedi, Chairman and Managing Director, UFlex Limited said, “We are producing this film at all our manufacturing facilities i.e. in India, UAE, Poland, Egypt, Mexico and USA. This speciality substrate is yet another example of innovation to create value added differentiation for our clients globally. Considering its superior barrier to oxygen, the film can be laminated with a sealant polymeric substrate to render a superior two layer laminate which is thin and light leaving much lesser carbon footprint at all the three stages of the product lifecycle i.e. manufacturing; transportation and disposal.”