About us

What we do?

UFlex is one of the world’s leading organizations that provides holographic anti-counterfeiting packaging solutions and brand protection solutions to its customers across the globe. The Holography Business of UFlex aims at developing and marketing holographic products & solutions that offer brand enhancement, textile value addition & enhanced aesthetic in packaging to various Government organizations and industry verticals globally. UFlex is also a certified printer by Indian Banks' Association (IBA) for printing of MICR instruments.

UFlex provides cutting edge technology to develop & produce its anti-counterfeiting solutions for augmented brand protection of goods and important documents.

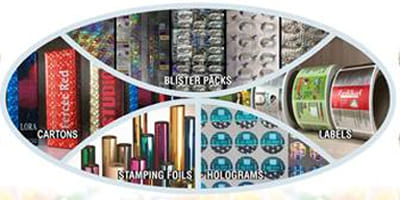

RANGE OF PRODUCTS

- Hologram with 2D Barcode for Track ‘n’ Trace

- Holographic Self-Adhesive Security Labels with Registered lens

- Multi coloured stamping foil for paper & board, textile, plastic, Leather, Digital application and document authentication (Hot & Cold stamping foil)

- Holographic Films (UV / HRI / Soft embossed / Hard embossed / Registered / Fresnel Lens Film)

- Holographic transparent BOPP film for Document & carton lamination

- Transparent Thermal film & Metallized Holographic Films, Soft-touch film, DC Special effect film & Cast ‘n’ Cure film

- Holographic Metallized Paper & Paperboard

- Textile Value Addition Products (Sequins/Hot Melt/ Glitter/ Fancy Yarn Film)

- Security Documents, Cheque Books, Mark sheet & Certificates

- Holographic PVC blister / Aluminium foil / Alu-Alu for pharmaceuticals

Production Facility

Our advanced manufacturing plants based in Noida & Jammu with revolutionary in-house manufacturing capability, cater to the requirements of large volume production orders to ensure the highest quality standards. These plants develop holography-based Anti-Counterfeiting Packaging and Brand Protection Solutions that help brands fight the threats of counterfeiting and safeguard their business interests.

The business is equipped with the following manufacturing facilities:

MANUFACTURING FACILITIES

- Mastering lab facilities

- Recombining facilities

- Electroforming process facilities

- Embossing facilities

- Lamination facilities

- Die Cutting facilities

- Coating facilities

- 1D/2D Barcode/QR Code/ Laser numbering facilities

- Metalizing facility (Aluminium & Zinc)

- Hidden features incorporation facilities

- Registered Lens Printing /Screen Printing

- UV Coding facilities

- Slitting / Micro slitting facilities

- Sequential numbering facilities

- Random numbering facility

- Hot Stamping facilities

- Flexo Printing facility

Machinery Photographs

Kinemax:

Metallizers:

Coating Facility:

Embossing Facility:

Paper label - Gallus EM 340 S:

Edale Beta 330-13’’

Operational Excellence

Operational Excellence isn't achieved overnight. It requires a high level of commitment, consistent, and concerted efforts to build & sustain a culture over time. The approach at UFlex ensures reliable and efficient production.

UFlex has adopted several measures towards achieving incident-free performance (safe working environment). We constantly tread on our “Goal Zero” philosophy that targets the elimination of incidents, defects and operational inefficiencies. Being world leaders in Holography, it is in our corporate DNA to ensure that we provide exactly what resonates with the client’s requirements at the most effective price coordinates. Our Anti-Counterfeiting Packaging applications and Brand Protection Solutions have so far safeguarded many domestic and global brands from counterfeiting threats and have also helped their products stand out on the retail shelves.

At UFlex Holography Business, our goal is to deliver quality that instills confidence in our discerning buyers around the world and also set a benchmark for others.

We remain determined in our adherence to excel at every stage of production, right from the selection of raw materials to development of brand protection solutions and anti-counterfeit technologies used across multiple industries in India and around the globe.

The UFlex Holographic Solution Advantage

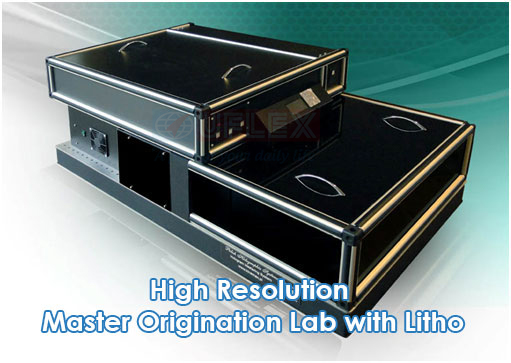

1. Mastering Facility:

- India’s best mastering lab

- Capacity to get the master ready within 6 hours

- Fastest delivery – Best results

- 1,20, 000 DPI

2. Security Facility in the Manufacturing Premises:

- The only Company with CCTVs, Internet AC’s systems with a strong room

3. Security Features in Holograms:

- 30 security features;

- Overt and covert animation;

- Impossible to copy

4. Technical Capability in Mastering:

- Can offer 1, 20, 000 DPI for sharp images with Litho.

- More security features.

5. Basic Raw Material - Polyester:

- In-house manufacturing facility;

- Faster supplies

6. Adhesive Sourcing:

- In-house manufacturing facility;

- WB, H.M; S.B. Heat Resistance up to 75-degree centigrade

7. R & D Department:

- In-house R & D

- New concepts every 6 months

8. Release Paper:

- Use of platinum base solvent less paper for better release

9. Laser / Inkjet / UV / Numbering:

- In-house facility sheet and spool forms used

10. Grade of Polyester:

- Super extra clear grade for extra clarity/ gloss

11. Lacquering/ Metallization/ Adhesive Coating:

- In-house facility;

- 06 metallizers running 24 hours;

- Consistent quality and innovation

- ZnS , Alox and Pattern Metallization

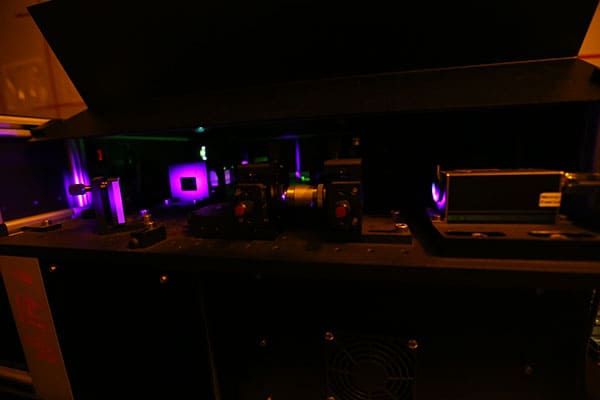

Research & Development

UFlex Holography Business has an in-house R&D facility and fully trained manpower that works hard to deliver unparalleled quality.We are equipped with avant-garde manufacturing facilities and enjoy technology tie-ups with world leaders. This provides us access to leading innovations in the industry and enables us to provide high end brand protection services and premium anti-counterfeiting packaging in India and around the world.

We ensure that the most advanced technology is at our disposal and the most efficient processes are in place. With a strong foothold in innovating products, solutions and design, the R&D Department of the Holography Business has consistently strived to refine and upgrade the processes for manufacturing of improved products. Our fully equipped research laboratory is a result of core technical strength & an unwavering commitment for manufacturing holographic products including holographic pouches, holographic films etc. In addition, a substantial emphasis is placed to ensure security while manufacturing the hologram. We pay utmost attention towards hygiene in relation to materials, processes, handling and storage.

The most essential pillar of the Holographic Industry is the secured execution & delivery of every job. UFlex ensures the same by installing a card access system, biometric technology (thumb recognition system), and in-house fully trained armed guards to restrict any unauthorized entry to the plant and maintain a high-level security zone.

Our recent development - Dyeable & Non-Dyeable films, provide a unique advantage of matching colors of sequins as per specific requirements, which otherwise becomes difficult to procure. Equipped with the world’s best and widest range of latest hi-tech machinery, we are capable of fulfilling all your holographic film requirements.