Products & services

The aseptic liquid packaging manufacturing facility of UFlex is the first of its kind, with a production capacity of 10 billion packs per annum. The plant is spread over 21 acres of the sprawling 72 Acres land parcel that UFlex has bought at Sanand, Gujarat.

UFlex’s Aseptic Liquid Packaging business offers a wide range of products under its brand name ASEPTO

Overview:

ASEPTO ASEPTIC PACKAGING MATERIAL FOR LIQUID PRODUCTS

Asepto packs are developed on the concept of 3P’s of packaging i.e. PRESERVE, PROTECT and PROMOTE. The Aseptic Liquid packs are made of six layers of packaging and are widely used to pack a range of beverages, dairy products and alcohol. Owing to our excellence in liquid packaging we cater to a large number of clients worldwide.

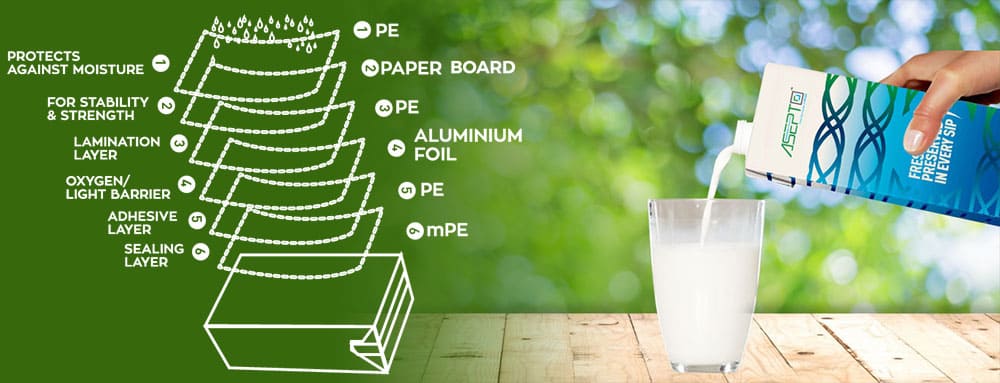

The packaging solution thus engineered is highly effective and optimised with the best material application comprising of paperboard, aluminium and polyethylene. All the raw materials used in development of packaging is food grade and complies with stringent quality and safety regulations.

THE ROLE OF VARIOUS CONDIMENTS MAKING FOOLPROOF ASEPTIC PACKAGING MATERIAL

- The high-efficient paperboard in our aseptic packs provide the required sturdiness and strength to the pack besides giving out a good surface for clear design printing.

- The aluminium foil layer provides a strong barrier for O 2 (oxygen) and light that protects the filled contents from the external environment.

- The inner layer made of polyethylene makes it possible to seal through the liquid.

This multi-layered development protects the packed contents from oxygen, moisture, direct light, and other environmental factors that keeps the liquid fresh in our aseptic packs and other packaging.

Aseptic liquid packaging increases the shelf life of the packed liquids and saves from dependency on the cold chain besides enunciating easy to handle-ability. Our Liquid packaging solutions have outperformed the expectations of many domestic and global brands and have written many success stories for our patrons across the world.

CONVERTING PROCESS

The converting process starts with the approval of design from the client. The approved design is fit into Asepto key line drawings as per the variant. The design thereafter is made on the flexo plates for printing.

The flexo plates are used for printing on to the hi-efficiency Asepto liquid packaging board with the possibility of printing up to 7 colours with inline creasing and punching facilities.

The paperboard further goes for the lamination process on the extrusion machine with aluminium film and layers of polyethylene to make a six-layered Asepto pack jumbo roll.

The jumbo rolls are split into single pack reels that travel through an automatic packing system where it is converted into desired pack size. The packaging material is shrink-wrapped for moisture protection, palletised by an automatic robot to avoid human touch and is further sent to goods warehouse through an automatic conveying system. This touch-free production process makes it most suited for liquid packaging needs by our clients.

In the complete process, the material is checked at each and every stage of operation and processed in a controlled environment under supreme hygienic conditions. The finished aseptic packs/cartons are run on filling lines and the desired product (juice, milk, dairy and distillery products) is filled through these Aseptic packaging filling machines.

One of the most endearing facts about the aseptic packaging material is the fact that it provides stiffness required to enable optimum utilisation of storage and transportation space, further bringing down the logistical and warehousing costs.

Overview:

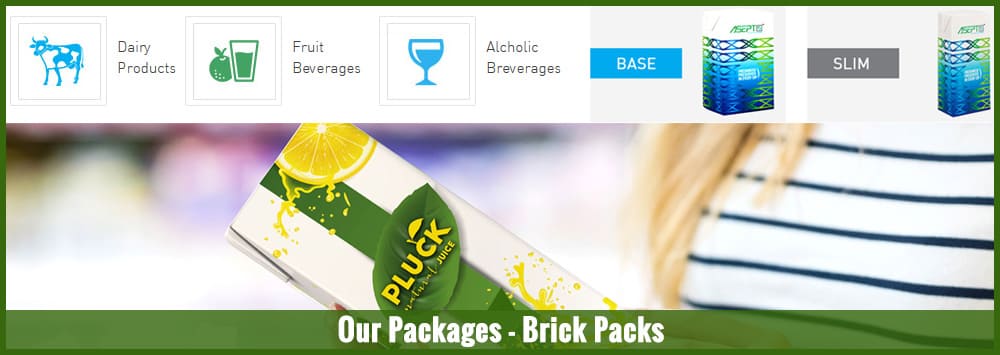

BRICK PACKS

Asepto brick packs are compact, energy-efficient, lightweight and multi-layered. The inclusion of high quality six layered materials of different combination offers strength and stability to the pack as per the packed product’s need.

Our packs retain the nutrition value, natural consistency, flavour and colour of Dairy Products, Juices, Alcoholic beverages, gels, powders, granules etc.

| Choose Size | Scissor | Perforation | Straw | PLH | Pull-tab | Recap |

|---|---|---|---|---|---|---|

| BRICK BASE PACKS TECHNICAL SPECIFICATIONS | ||||||

| 100ml | ||||||

| 250ml | ||||||

| 1000ml | ||||||

| BRICK SLIM PACKS TECHNICAL SPECIFICATIONS | ||||||

| 125ml | ||||||

| 160ml | ||||||

| 200ml | ||||||

| 1000ml | ||||||

TRIO Packs

In today’s competitive market, packaging cannot be alienated from the over-all experience the end users get. Besides imparting visually stimulating aesthetics for the end-users at the point of sale (POS), packaging also offers enhanced functionalities, extends shelf life by imparting optimized barrier properties and also provides a safety net from fake and spurious look-alike products through impregnable brand protection / anti-counterfeiting solutions.

ASEPTO Trio packs are designed keeping in mind the end user’s perception of overall packaging and product experience. The pack comes in various formats like 65ml, 90ml, 110ml & 150ml and is a perfect format for small quantities of Liquid Packaging. The packs have an easy opening mechanism from perforation for paper straw that further enhances user’s consumption experience

| TRIO PACKS TECHNICAL SPECIFICATIONS | ||||||

|---|---|---|---|---|---|---|

| Choose Size | Scissor | Perforation | Straw | |||

| 65ml | ||||||

| 90ml | ||||||

| 110ml | ||||||

| 150ml | ||||||

Pillow Packs

In today’s competitive market, product packaging is equally important as the product itself. Beside the fact the visual appeal of your liquid, juice or beverage package design, usability and consumer preference is significant. Pillow packs are widely used for packaging of dairy requirements and is consumed by every household on a daily basis.

Pillow packs are a combination of the good old design and modern-day aseptic technology. These packs give a feeling of comfort and nostalgia along with a blend of new generation aseptic protection to our customers. Pillow packs are widely used to pack daily staples such as milk, curd, ghee etc. Pillow packs are available in 70ml, 200ml, 250ml, 500ml and 1000ml pack size.

| PILLOW PACKS TECHNICAL SPECIFICATIONS | ||||||

|---|---|---|---|---|---|---|

| Choose Size | Scissor | |||||

| 70ml | ||||||

| 200ml | ||||||

| 250ml | ||||||

| 500ml | ||||||

| 1000ml | ||||||

Overview:

Our Unique Design Technology

ENHANCING SHELF IMPACT AND DELIVERING FUNCTIONAL EXCELLENCE!

As one of the leading beverage packaging companies and premium liquid packaging solution company, we truly understand the merit of standing out of the clutter and the struggle to get noticed in an already inundated retail shelf. Packaging plays a key role in a customer’s buying decisions and facilitates the first trust with them.

Packaging serves as the last mile salesperson for a brand, and a lot rests on its shoulder, in terms of engaging the customer at the point of sale, to transcending this interaction to a successful transaction and finally till the point of consumption. Brands are focusing a lot on developing innovative packaging to meet their liquid packaging requirements.

With a rich pedigree of pre-press capabilities, efficient converting technology and unmatched packaging finesse at our disposal, we can evoke a ‘WOW’ factor for your product. Our packaging design technology includes an optimised blend of enhanced aesthetics, colour schemes, shapes, functionalities and brand protection features among others.

Our hi-specification paperboard and printing technologies do everything right from real-time color monitoring, defect detection and rendering seven-colour output all at lightning-fast speeds. This enables quick turnaround, in terms of high quantities of precisely sized sheets for undertaking specific packaging production runs, simultaneously, optimising efficiency and minimising waste.

Our metalized packs are a new offering for the industry that offers unique metallic effects on the torso of the pack obtained through Flexographic Printing Technology. The integration of metallic impressions changes the visual identity and creates a lasting impression on the packs. The 7 colour play printing is an added advantage of our product bouquet.

Our approach is to create innovative printing which gives a distinct appeal to the packs drawing the attention of customers at the “Point of Sale”.

Designing Functional Excellence

We take care of your product’s need and are cognizant of your brand image as well. With true serenity, we are committed to do whatever it takes to add value to your product’ packaging so that it appears differently on the retail shelves.

Our aseptic liquid packs not only suffice the customers’ aesthetic needs but also bestow additional opportunities of functionally driven solutions. So, every little concern you have regarding your brand’s packaging solutions, you can pin it on us and we’ll provide you with the packaging solution that best suits your product requirement.

Our packs offer user convenience, easy opening, and extended shelf life to liquids such as Juices, Non-aerated alcoholic beverages, and highly perishable liquid consumables such as Milk and other Dairy products. Our packs are designed to create a shelf impact, and their impervious nature prevents spoilage, thus the products do not require refrigeration until the time of consumption.

Our packs are available in consistency ranging from low viscosity to high viscosity easy flowing and easy pourability; the packs are combined in lean body designs to promote convenience of carriage and transportation.

We have the capability and technical expertise to develop anti-counterfeiting solutions that protect your brand from duplication.

High Functional Smart Lines:

Asepto Smart 78

Revolutionizing the concept of aseptic liquid filling, ASEPTO holds avant-garde liquid filling infrastructure. ASEPTO boasts of having ‘Smart-78’, an aseptic liquid filling machine , is a shot in the arm of liquid packaging solutions that assures power, performance and sophisticates the process of liquid packaging.

The one-of-its-kind machine, fully integrated with the latest technologies, is highly automated and allows a smart approach for operational efficiency. In fact, the operational cost of the machine is much less with an optimal (low) TCO (total cost of ownership).

The power-packed aseptic liquid filling machine is a significant step ahead of the erstwhile aseptic liquid filling machines, delivering an output of 7,800 packs per hour. ASEPTO Smart-78 is designed to process packs 100ml, 125ml, 160ml and 200ml for convenient and smart packaging needs meeting desired customer expectations.

More About The Filling Machine

Technical Support

We understand "Your every single minute is precious!"

For uncompromised productivity & performance, we offer technical support to our clients and assist them with real time intervention to ensure operational continuity.

The concept of Aseptic liquid packaging requires special technical skills and expertise. We offer end –to-end support, ensuring packmat machine interface that includes assistance and maintenance of packaging material from concept till commissioning. It is only due to the support we offer, that we have made a mark as a preferred aseptic liquid packaging in the industry. We are determined to continue our support once we complete setting-up of our U-shaped paper straw manufacturing line at our aspetic liquid packaging facility in Sanand.

As the Aseptic liquid packaging brand of UFlex, we go the extra mile with our support to clients.

- On Ground Technical Assistance -From incident to resolution, our technical assistance team offers pre-requisite resources to resolve the issues and make a turn-around in the shortest possible time. From dedicated personalised system engineers, to comprehensive packmat machine management, we are well equipped to provide best-in-class service experience.

- System Specific Engineers - Dedicated specialised engineers with hands on experience in handling various formats/systems of aseptic machines to provide quick resolutions.

- Performance Maintenance Services – Our team defines the life cycle of every component of our aseptic machines to maintain the efficient performance of the lines. In tandem with the clients’ requirements, the team evaluates and schedules maintenance and service visits. The goal is to unleash the operational capacity of every unit, minimise downtime, and optimise overall cost of ownership.

- Packmat Machine Interface - Our team of experts ensure 100% compatibility of packmat with the aseptic filling lines to produce desired packs and formats right from portion to family pack.

- Package Quality Assurance – We assure packs’ integrity to produce a zero defect package. Pack sealing is tested in our quality lab and on site during the production process.

- Timely Delivery of Authentic Spare Parts - Timely delivery of authentic spare parts is the most critical facet to ensure production continuity that yields maximum value to our clients. With in-house production of our Aspeto filling lines and stocked spare parts we ensure fastest delivery while maintaining quality and performance of machines supplied to the clients.

- Skill Training Services - We consider staff and stakeholders’ continual training with regards to the use and know-how of packmat and machines as an integral part of incrementally enhancing the overall Aseptic packaging experience simultaneously ensuring business continuum.

To Know More About Aseptic liquid packaging, Visit Asepto Website www.asepto.com